Back to AIHPA Home Page

![]()

Crushed Corn Cob -

polishing / blasting / tumbling media

- Tikka T3 Match Rifle Tube Stock

- Tikka T3 magazine options

- Crushed Corn Cob - polishing tumbler media

Back to AIHPA Home Page |

Australian International High Power

Crushed Corn Cob -

|

Other items of interest: - Tikka T3 Match Rifle Tube Stock - Tikka T3 magazine options - Crushed Corn Cob - polishing tumbler media |

Crushed Corn Cob has been used as polishing media for many years. When it comes to friction polishing media, it is very hard to beat - due to its excellent natural qualities. Why?

Vibratory finishing and tumbling in a tumbler are mass finishing processes where abrasive and absorbent characteristics are often both desirable. Corncob grit is very good at retaining the added polishing compound, and hard enough to cut away dirt without the damage to surfaces.

Corn Cob Grits with a suitable polishing compound is an excellent Abrasive & Absorbent Media suitable for use in Polishing, Drying, soft De-burring, De-flashing, Blast cleaning of Engineerd Metal & Plastic components/parts. It is completely naturally Biodegradable and does not stick the components while being used for removal of Moisture, Oil & Grease, imparting Surface finish, Luster/Gloss & soft De-burring of components. It is suitable for use in Tumbling Barrels/Drums, Vibro Finishing M/c, Herperisers, Centrifugal M/c, Rotary Drum Dryers, Sand Blasting M/c, etc.

This product is ideal to polish brass, silver, and other non-ferrous metals in a vibrating tumbler. Shooters of pistol and rifle have used this product as a base to polish their cartridge cases for years and most all polishing media for case cleaning commercially has been crushed corn cob.

Grit blasting with corn cob particles is accomplished with the same equipment as used for sand blasting. Because corncob grit is considerably less aggressive than sand, it is often categorized as a "soft abrasive" (corncob grit has a 4.5 Mohs hardness). Corncob grit does not etch glass or foul bearings and is frequently used to clean electric motors and machinery with hydraulic cylinders. Other applications include: smoke damage and residue clean-up; mould cleaning; plant maintenance; and loose and flaking paint removal. It is ideal for wood, aluminium and fiberglass substrates.

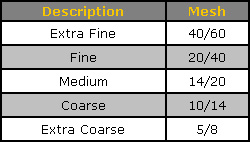

We carry

10/14

grit crushed corn cob only. Other sizes shown for comparison only.

Do NOT pay typical retail prices. We have seen 2lb (less than 1kg) bags for $10-15 per bag in shops. CRAZY! Just buy this dry corn cob, add a non wax liquid car polish and done...

A$55/20lt plastic resealable drum ea, plus postage and handling.

OR

10kg heavy duty paper breathable bag for A$50ea plus postage and handling.

We do NOT sell in smaller parcels, nor do we sell product in other mesh sizes.

email us:

![]()

![]()