To AIHPA Home Page

![]()

MAGAZINE CARE AND MAINTENANCE

Other items of interest:

- Tikka T3 Match Rifle Tube Stock

- Tikka T3 magazine options

- Crushed Corn Cob - polishing tumbler media

- Pac-Nor Match Rifle Barrels

- Krieger Match Rifle Barrels

To AIHPA Home Page |

Australian International High Power

MAGAZINE CARE AND MAINTENANCE |

Other items of interest: - Tikka T3 Match Rifle Tube Stock - Tikka T3 magazine options - Crushed Corn Cob - polishing tumbler media - Pac-Nor Match Rifle Barrels - Krieger Match Rifle Barrels |

WATERS RIFLEMAN - MAGAZINE CARE AND MAINTENANCE

-

Tikka

- Lithgow

Your mag is sent without any form of lube. A very light application of dry lube to mag internals is recommended.

Below is the latest instruction for assembly, care and maintenance for your Waters Rifleman magazine…

MAINTENANCE

Your WR mag should last you a long time. This is the mag of choice by many champion shooters at national and international level, so you may want it to last, hence the need for care:

CHECK FIT: The WR mag is made to 0.1mm tolerances. The rifle receiver, stock and floorplate may vary up to nearly 1mm. The mag may be tight to insert and remove. Remember, this is a precisely made magazine (perhaps too precise). There are tolerance differences from rifle to rifle, and action take-down screws can be done up to different tension (sometimes too much). If you think it will never improve, then simply use a "smooth" (fine) file and take 0.1mm increments off the magazine latch locking tang, continuously testing fit as you go. DO NOT REMOVE more than 0.1mm at a time between testing.

BED IN: When you first purchase a WR mag, the follower may be "too sharp" or “too new”. The follower works best after it has cycled a few times to bed into the precise shape of mag internals. This will come with use, but this can be expedited by manually depressing and releasing the follower. If manually wearing by hand, BE SURE to move the follower up and down squarely, such as it would when used in the rifle (ie. avoid tipping, stressing the follower, etc).

ASSEMBLY

a) CLEAN: Clean the mag internals with a suitable solvent, removing all grease, oil and dirt debis.

b) DRY LUBE: Always dry-lube the internal of the mag. Dry lube need be applied to FRONT and REAR internals of the follower chute (should not be needed on the sides, but wouldn’t hurt). The most common dry-lubes are Graphite powder, PTFE (Teflon) drying spray, or Silicone spray (non-greasy) drying. Do not use oil, grease or similar.

c) CHECK: Ensure the follower flows freely in both halves before putting together. If it does not, there may be some foreign matter, damage, or the follower might be too new/tight. The follower and internals are made to a tight tolerance at 21deg C, so the follower may need to wear a little. Expedite the wear by considering filing a little material out of front centre of the follower (so there is a convex curve to suite the front curve of mag internal).

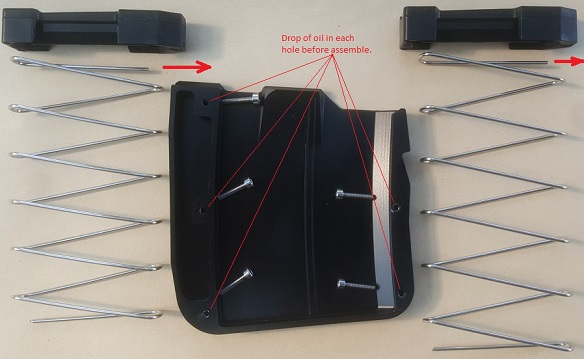

d) ANTI-SEIZE: Apply a tiny drop of an anti-seize to the clam screw threaded holes. Or, apply a small drop of synthetic oil. This prevents the threads from “binding” due to Alum and SS electrolysis. DO NOT allow oil or grease to run into the mag internals - oil and ammunition do not mix.

e) SPRING DIRECTION: Note, the spring tail at the top into the follower should point forwards, towards the front of the follower/mag (the base may be opposite facing, depending on mag model).

f) ALIGN: Be sure to align the 2 body parts as best as you can. There is 0.05mm play in the screw holes, so it may require some manual alignment as necessary. BE sure there is no foreign matter on the mating surfaces.

g) TIGHTEN: Screws should be done up pinch tight (do not over tighten). Be sure there is no foreign matter in the threaded hole. Apply a drop of synthetic oil or anti-seize applied to screw or in thread hole first (see above).

h) TUNE: If you are heading to a world championship, and performance is critical, you might want to "tune" the performance of the stripping force by very fractionally re-forming the spring free length. Be sure to NOT allow the spring to form a helical shape - twist with the coil direction while stretching.

- 223 6

shot 80mm Free Length

- 223 10 shot 130 FL

- 6BR/250 6 shot 130 FL

- 6BR/250 10 shot 170 FL

- 308 6 shot 130 FL

- 308 10 shot 170 FL

- x55 & 3006 6 shot 130 FL

- x55 & 3006 10shot 170 FL

If you feel you want less pressure, you can try to elongate the spring coil rate OR cut off half a coil of spring at a time to get desired pressure. Remember to take small increments at a time.

i) TEST: When assembled, test carefully. Take any appropriate corrective action. If in doubt, ask.

FIT & FUNCTION: We let uses of these magazines do the talking for us...and their comments thus far have been tremendously positive. We made these magazines for the fastidious shooter that wants the BEST match grade magazine available. Likewise, shooters of the Waters Rifleman mags are expected to have a fundamental understanding of how magazines work - understanding tolerances, temperature change, round stacking geometry, etc. This is precision equipment, and precision is not sacraficed. Your magazine should be maintained. Click here for details:

DOESN'T FIT. There have been the odd occasion where a shooter magazine will not latching/clicking in place easily. We believe this is due to an intolerance of the rifle stock during moulding, or possibly swelling from moisture, or by over tightening of the stock take-down screws, or a number of other things. Also, some shooters are bedding their receivers, which increases the receiver height from the floor of the stock. Our mags are made to factory spec plus or minus 0.1mm, and from billet aluminium that won't suffer post machining change. If the magazine is too tight to latch, the only option is to file off material from the bottom of the latch tang. on front of mag. in 0.1mm increments until it clicks in. Don't worry about removing the black, as this will thin out with regular use anyway. The alternative is to shim the floorplate with some very thin material (eg. cut shims out of alum can). There is nothing wrong with the mag. Again, precision to a standard can result in issues due to variance in the rifle. Part of the game... Your magazine should be maintained. Click here for details:

TIGHT IS BEST: Ensuring a tight and solid fit keeps your repeater rifle as close to performance as a bolt action single shot rifle. Tight and solid assembly and fixing keeps harmonic vibration even through the whole rifle system, and helps dampen the vibration quicker and minimise vibration intensity spots.

MARKING AND SACRIFICE: This magazine is made of metal. Metal on metal will always result in witness marks. Use of the WR mag will result in witness marks on the aluminium magazine body. This is always going to happen, and is preferred to protect undue wear in the more expensive rifle receiver. The sacrificial wear areas are the front latch tang, rear top flat where mating the trigger front tension leaf spring, and the top rear pivot corners. Witness marks can be marked over with black.

![]()